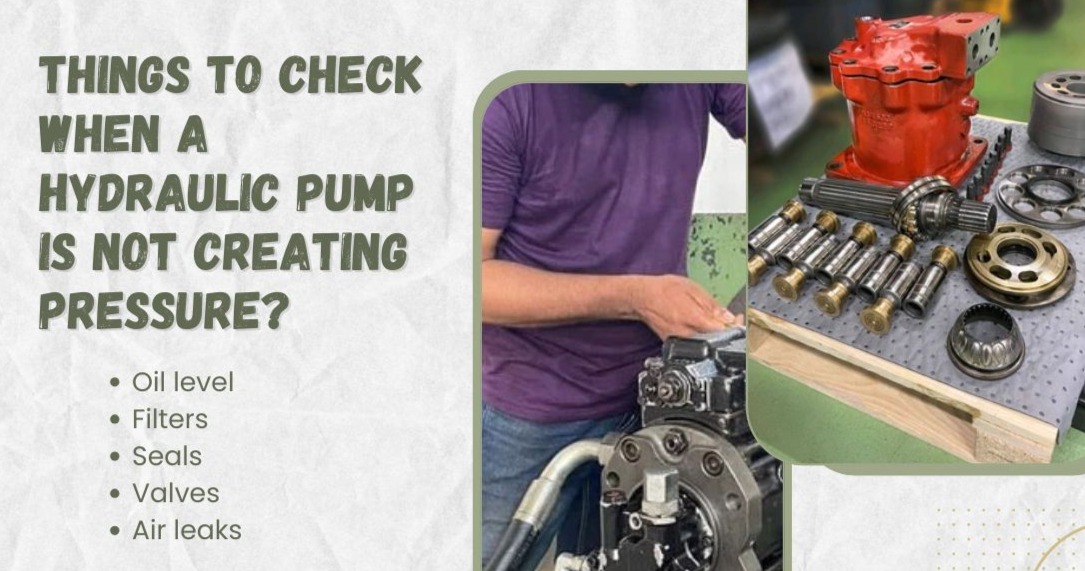

Anyone who has spent time around hydraulic machines knows the feeling when you hit the switch, everything seems normal, but the pump just won’t build pressure. The motor is running, yet the machine feels weak, almost useless. Most people assume the pump itself is dead, but that’s not always true. Many times it is the tiny things, loose fittings, tired seals, or skipped maintenance that bring the whole system down. Before you panic, it’s worth checking these common troublemakers. Let’s go through them one by one.

5 Common Problems That Can Occur in Your Pump

1. Air Sneaking Into the System

A pump is designed to push oil, not air. The moment air sneaks in, pressure starts dropping. You can sometimes hear strange whining, or foamy bubbles in the tank. I’ve seen this happen often because of a loose joint, a bad seal, or even a small crack on the suction pipe. One quick check is the oil itself if it looks frothy or cloudy, air has already found its way in.

2. Weak or Damaged Seals, Hoses or Cylinders

It’s easy to overlook the importance of cylinders, hoses and seals. Even a small crack or hardened seal may allow oil to leak, and that small leak means the pump will not be able to hold the proper pressure. Be on the lookout for wet spots, bulges on hoses, or slow drips around fittings. If you discover these tiny leaks early enough, simply changing the defective hose or seal or a complete hydraulic cylinder repair can visually save the complete system from serious damage. Many technicians will tell you that ignoring these small parts ends up costing more than replacing them in time.

3. Dirty or Blocked Filters

Hydraulic oil has to stay clean to move smoothly. Filters are like the lungs of the system; they trap dirt, dust, and small metal pieces before they get inside the pump. But once the filter is clogged, oil flow gets restricted, and pressure drops. Sometimes, modern machines even flash a warning light when the filter is overdue for replacement. Don’t wait for that stage; it’s cheaper to stick to the replacement schedule. In dusty or heavy-duty work areas, checking filters more often is always a good idea.

4. Low or Wrong Hydraulic Fluid

Believe it or not, many pump issues come down to something as simple as the oil. If the tank is running low, the pump just can’t build pressure, no matter how strong the motor is. I’ve seen machines struggle just because someone forgot to top up. Another mistake is using oil that isn’t meant for the pump too heavy, too light, or just not the right type. The safest bet is to stick with what the maker suggests and keep an eye on the level every day. It’s a two-minute check that can save you hours of headache.

5. Internal Wear and Tear

Over time, pumps do wear out. The gears, pistons, or vanes inside lose their efficiency due to friction and long hours of use. When that occurs, the pump can’t generate enough pressure even if the motor is turning. If you’ve checked hoses, seals, oil, and filters, but are still not achieving pressure, it may mean that the pump itself needs rebuilding or replacing. At that point, you should have a qualified technician contact you because they have the proper tools and knowledge to accurately determine the cause.

Known More- What Should Be on Your Hydraulic Pump Checklist?

Final Word

Just because a pump isn’t building pressure doesn’t automatically mean it has failed. More often, small issues like air leaks, clogged filters, or worn-out seals are the real culprits. That’s where Hydraulic Repair for Construction Equipment plays an important role—by identifying and fixing these minor problems before they turn into major failures.

By carrying out routine inspections and replacing parts before they wear out completely, you can keep your equipment running smoothly and avoid costly repairs. In short, looking after the little details today helps your hydraulic pump system stay dependable for the future.